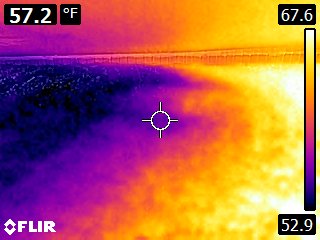

This service is provided in a weekly basis (once a week) and starts after the bin is full until holding temperature is achieved. After that, is up to the client the frequency of visits. Guidelines for management of proper temperature, airflow, and humidity during the four stages of potato storage management – removal of field heat, suberization, cool down, and holding period are developed. A complete storage evaluation, including air measurements and the use of an infra-red camera to detect insulation problems are included in this service. Early, mid and late storage evaluations are detailed separately.

Early Storage: a complete storage inspection is done during this visit.

- Air velocities are measured for all laterals and total CFM for the storage is calculated.

- Detection of air flow problems in laterals.

- Calculations on air velocities in plenum, humidicell, exhaust, return and fresh air intake

- Recommendations on minimum air capacity for the storage.

- Plenum, top of pile and return temperatures are measured.

- Relative humidity in plenum and top of pile are measured.

- Measurements are compared towards panel box data.

- Humidity system inspection.

- Temperature and RH sensors calibration recommendations.

- The entire top surface pile is scanned for temperature.

- Temperature gradient between top and bottom of pile is calculated.

- The entire building is scanned for temperature leaks through doors and insulation problems are detected using infra-red camera.

- Storage Best management recommendations are developed based on measurements, weather and tuber condition.

Mid Storage: plenum and top of pile inspection is done during this visit.

- Lateral air velocities are re-measured if bin is partially filled.

- Plenum, top of pile and return temperatures are measured.

- Relative humidity in plenum and top of pile are measured.

- Measurements are compared towards panel box data.

- Humidity system inspection.

- Temperature and RH sensors calibration recommendations.

- The entire top surface pile is scanned for temperature measurement.

- Best management recommendations are issued based on measurements, weather and tuber condition.

Late Storage: plenum and top of pile inspection is done during this visit.

- Plenum, top of pile and return temperatures are measured.

- Relative humidity in plenum and top of pile are measured.

- Measurements are compared towards panel box data.

- Humidity system inspection.

- Temperature and RH sensors calibration recommendations.

- Conditioning planning for shipping.

- Best management recommendations are issued based on measurements, weather and tuber condition.